Ultramarine Blue Colorants: Versatile Color Solutions for Plastics, Paints, and Inks

Ultramarine blue remains one of the most widely used pigments in use today. From its historic use in fine art to its extensive application in contemporary industries, ultramarine pigments have proven themselves as both visually captivating and technically reliable. Known chemically as Pigment Blue 29, ultramarine blue offers a blend of intense color and strong performance, making it ideal for applications in a wide range of materials and products.

Understanding Ultramarine Blue’s Chemistry

Ultramarine blue is a synthetic inorganic pigment primarily made from sodium aluminosilicate and sulfur. Its distinctive deep blue color with violet undertones derives from the complex lattice structure created during calcination. Once sourced from lapis lazuli, the pigment is now industrialized to ensure consistent shade and quality. Pigment Blue 29 has become a standard due to its safe nature, strong chemical resistance, and resistance in outdoor environments.

Using Ultramarine Blue in Plastic Manufacturing

Ultramarine blue for plastics is highly valued for its ability to endure high processing temperatures without losing color integrity. Whether it's polyethylene, polypropylene, PVC, or polystyrene, the pigment remains unchanged, avoiding bleed or migration. Its resilience against heat and UV light makes it suitable for both interior and exterior plastic products.

You’ll find ultramarine blue in a wide array of consumer goods, where its compatibility with numerous resins allows for smooth dispersion and consistent color in extrusion or molding processes.

Use of Ultramarine Blue in Paints

In paints, ultramarine blue delivers a vivid, matte finish ideal for decorative and industrial purposes. It is used in both water- and solvent-based systems. Thanks to its UV and alkaline resistance, it performs reliably in exterior applications.

Ultramarine pigments are also used to tint white paints for subtle tones or formulate bold, expressive blue finishes. Artistic paints, primers, and wall coatings benefit from its lightfastness and easy blending characteristics.

Inks and Printing Applications

Ultramarine blue for inks is appreciated for its vivid tone, non-toxic composition, and versatile behavior. It is commonly used in printing inks for labels, packaging, security documents, and textiles. The pigment integrates well in various systems such as flexographic, gravure, and offset, ensuring sharp imagery and color retention.

Because it is chemically inert, ultramarine pigment doesn’t react with other ink ingredients, resulting in extended shelf life and consistent performance.

Role in Masterbatch Formulation

Ultramarine blue in masterbatches ensures precise color delivery and simplified production processes. It’s pre-dispersed in copyright resins, making it easy to blend with base polymers. This results in even coloration across finished products.

Masterbatch makers value ultramarine blue for its excellent tinting strength, broad compatibility with polymers, and thermal and chemical durability. It’s a go-to choice for producing blue packaging films, fibers, and molded plastic parts.

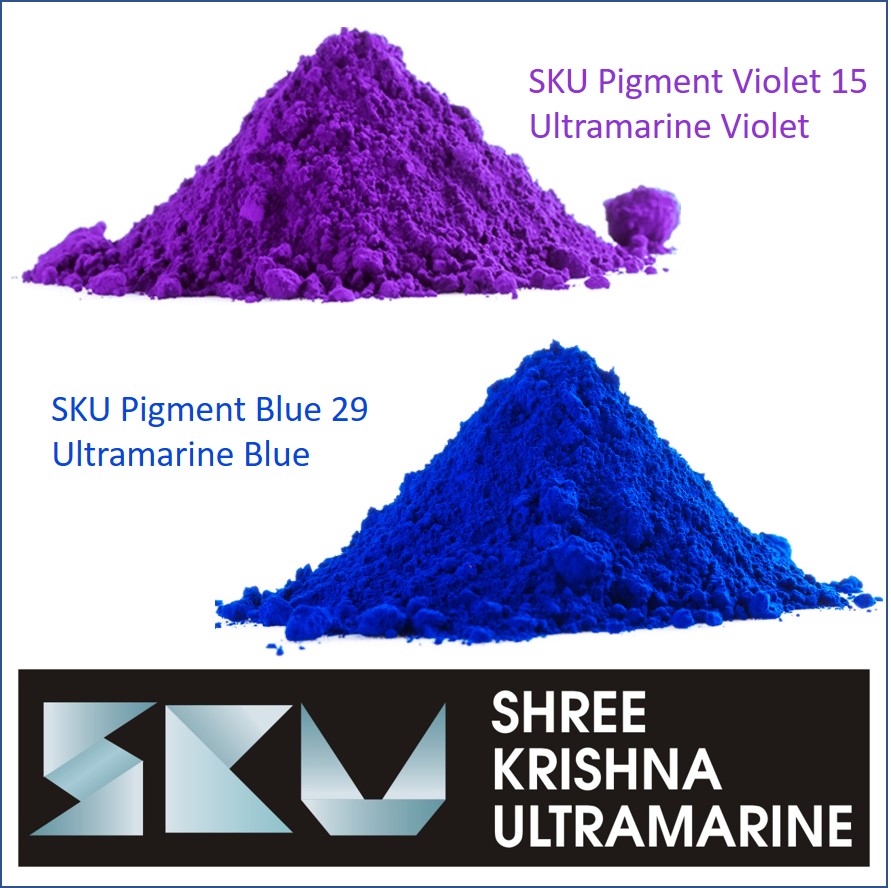

Exploring Ultramarine Violet

In addition to the classic blue, ultramarine violet provides a cooler tone with purple nuances. This shade is made by modifying the sulfur levels during manufacturing. Ultramarine violet is popular in cosmetic products, artist paints, and decorative coatings where subtle, elegant tones are important.

It maintains the same benefits as ultramarine blue, such as lightfastness and non-toxicity, while offering a sophisticated visual option for specialized uses.

Why Choose Ultramarine Pigments

Ultramarine pigments are safe, economical, and eco-conscious. They are free of heavy metals like cadmium or lead and comply with regulations for food packaging, children’s toys, and cosmetics. Their ability to resist harsh chemicals and alkalis ensures durable performance in challenging environments.

In industrial settings, these pigments are easy to handle, don’t stain equipment, and disperse quickly—leading to efficient production and less downtime.

Choosing a Reliable Ultramarine Blue Manufacturer

Partnering with a trusted ultramarine blue manufacturer is essential to ensure pigment consistency and compliance. Reputable suppliers use Ultramarine Pigments modern technology, rigorous quality controls, and environmentally friendly processes to deliver top-grade pigments.

A good supplier offers a diverse pigment portfolio including blues and violets tailored for inks, plastics, paints, and masterbatches, along with technical support, certifications, and customized packaging options.

Understanding Pigment Blue 29

Pigment Blue 29, the technical classification for ultramarine blue, is a silicate-based pigment recognized by CAS number 57455-37-5. Its unique composition provides strong tinting power, opacity, and stability up to 350°C.

It is accepted in a broad range of applications and listed with international bodies like REACH, TSCA, and EINECS. Its consistent hue and high heat resistance make it one of the most trusted inorganic blue pigments worldwide.

Eco-Friendly and Safe Characteristics

Ultramarine pigments align with the global movement toward green manufacturing. They are non-toxic, free from dangerous substances, and do not generate harmful waste during production or use. Their inert nature makes them suitable even for close-contact applications such as cosmetics and kids' products.

Leading pigment producers are also adopting eco-conscious practices like waste recycling, low emissions, and energy-efficient production to support corporate sustainability goals.

Ultramarine Blue in the Global Market

Demand for ultramarine blue is on the rise across Europe, Asia, and the Americas, driven by growth in packaging, construction, textiles, and automotive sectors. Industries are increasingly seeking vibrant, safe, and durable pigments.

New trends include pre-dispersed ultramarines, hybrid pigment blends, and enhanced dispersion technology—all contributing to greater efficiency and customization in manufacturing workflows.

Conclusion: Ultramarine Blue’s Timeless and Practical Appeal

Ultramarine blue continues to be a preferred pigment across multiple industries, valued for its brilliance, durability, and non-toxicity. Whether used in technical or artistic applications, it consistently delivers reliable results.

By partnering with an experienced ultramarine blue manufacturer, businesses can ensure product integrity and regulatory compliance while keeping costs low and sustainability high.